Today at Advent we introduce the term Li.F.E.TM technology for Liquid Fuel Electrochemical engines.

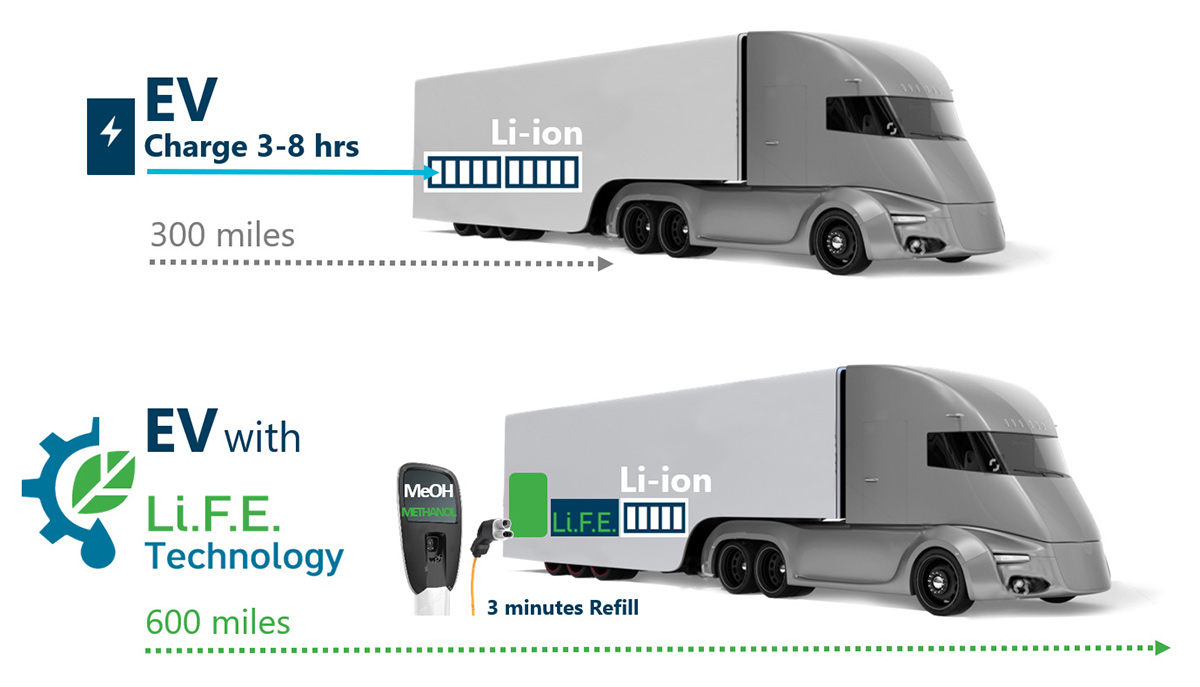

Advent’s Li.F.E.TM technology enables companies in automotive, marine, drone, aviation, and heat&power markets to build clean electrochemical engines that work with liquid fuels (like methanol) and also natural gas or DME (dimethyl ether) to produce electricity from a fuel cell. In a typical Li.F.E. vehicle, the fuel cell consumes methanol to generate electricity that recharges the Li-ion battery continuously. This configuration eliminates the recharge time problem, doubles vehicle range, and reduces the battery size in half, thus accelerates the electrification revolution and solves the problem of hydrogen availability, as hydrogen infrastructure would require big investments worldwide.

Advent’s Li.F.E.TM technology consists primarily of the Membrane-Electrode assemblies that are the heart of the fuel cell but may also extend to the overall fuel cell design. At Advent, we are continuously trying to improve the technology that can drive electrification to the level of mass-adoption worldwide.

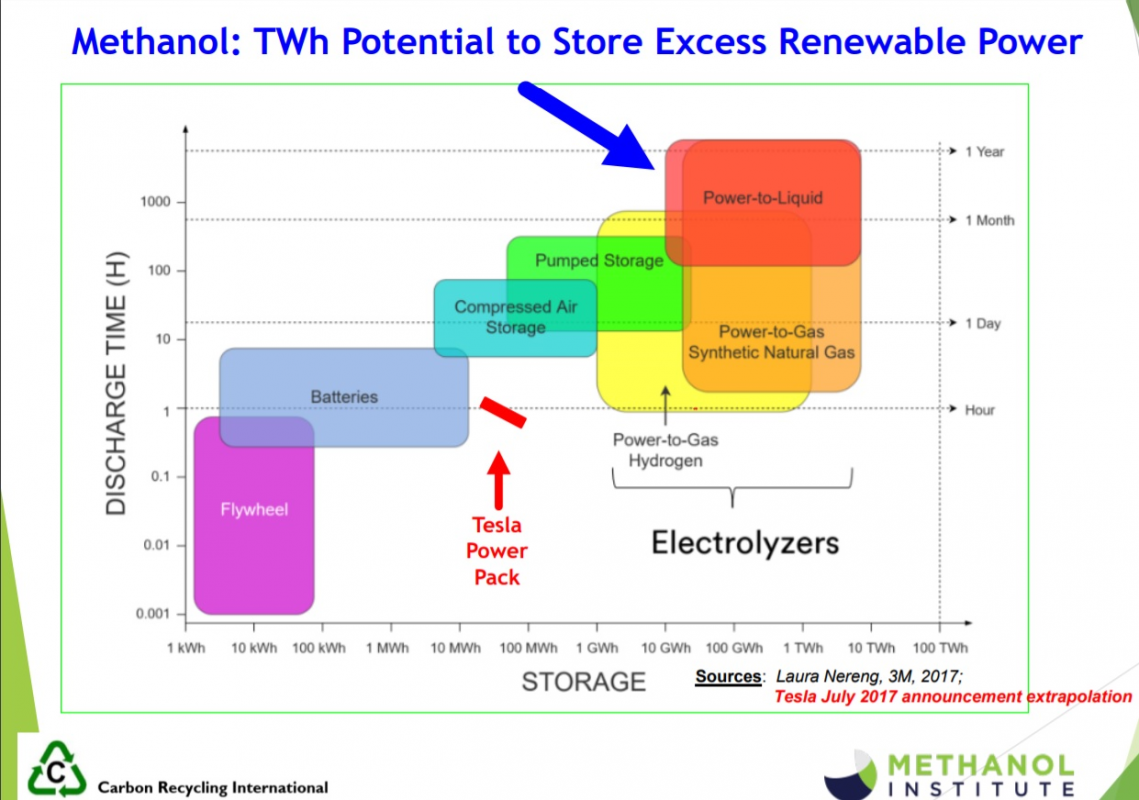

The inspiration for the term Li.F.E.TM comes from the vision of green methanol production. Innovative companies are already producing methanol by combining CO2, renewable electricity, and water. The rising methanol economy is carbon-neutral, producing and consuming CO2 at equal rates, bottling sunshine and wind in liquid form. Liquid renewable energy can be stored and transferred easily with minimal infrastructure investments.

We can continue to use with minor modifications existing gas stations, trucks, tankers, ships and even pipelines, while we would be contributing zero pollutants and zero net CO2 to the atmosphere.

The Li.F.E.TM will solve in an economical and feasible way the number one problem of the 21st century: The need to balance energy needs, economic growth, and environmental concerns. By bottling methanol and using it in Li.F.E.TM engines operating with Advent’s Li.F.E.TM technology to generate electricity we can foresee a future of economic growth and energy security for the ten billion people that will live in the planet by 2050.

Li.F.E.TM imitates life. Photosynthesis and Electrochemical Engines.

Li.F.E.TM and life itself have a lot in common. In nature, plants use CO2, water, and sunshine to create through the catalytic process of photosynthesis glucose and the energy that they need to grow and create new life. The process has worked for 700 millions of years and has recycled CO2 and water efficiently and in a stable way across the planet. We are now in a position to replicate this process for our own needs creating a fully recycled carbon-neutral energy and industrial ecosystem.

Sustainable Methanol Economy Production Ecosystem (Green & Gray production)

Using the Li.F.E.TM term

We welcome all our customers or partners that are deploying or testing Li.F.E.TM technology to adopt the term, in a joint effort to communicate the future of electrification.

Advent’s focus is on developing best-in-class Membranes and Electrodes and the assembled MEAs. We envision hundreds of manufacturers in different industries will develop Li.F.E.TM engines with Li.F.E.TM inside technology from Advent.

The story behind the name

Back in 2018, when we sat down at Advent to hone our marketing strategy, we were faced with a problem: naming our key product. We had a great name in “Advent.” It doesn’t limit the company as “Fuel Cells & Bells Co.” or “Li-Ion King Inc.” would. “Advent” conjures notions of the arrival of something important, maybe of adventure. The inspiration is from the combination of the terms “Advanced Energy Technologies.” Simple and clear when it needs to be so, vague if it has to. In technology we live in dog-years thus what is advanced technology in 2020 may be obsolete by 2030.

The problem we had to face is the name of the product. Advent develops, manufactures and sells MEAs (membrane-electrode assemblies). A membrane-electrode assembly consists of a proton conducting membrane sandwiched between two sheets of electrodes (the anode and the cathode). When stacked in parallel and separated by bipolar plates this configuration, the fuel cell, can produce electricity given hydrogen and air as inputs. The technology PEM (Proton Exchange Membrane or Polymer Electrolyte Membrane) is known across the electrochemical industry as a PEM fuel cell.

PEM fuel cells are a potential solution to transportation, portable and stationary power, enabling electrification without pollution. In a KPMG survey, 78% of automobile industry leaders said that fuel cells, not batteries, will be the eventual solution to clean transportation. Many great companies have brought the PEM technology to the level of reliability and pricing that make it feasible for mass-market application. But there is a catch: availability of hydrogen. The infrastructure needed to transport and refill our cars and other electrical engines with hydrogen world-wide would cost trillions of dollars. The amount for China alone having 200 cars per 1000 people is close to $3 trillion in new infrastructure. It would also mean that we need to replace our current infrastructure of ships, tankers, trains, trucks and gas stations.

Advent Products

Advent’s technology is based on htpem or ht-pem or High-Temperature PEM. High-Temperature PEMs are phosphoric-acid instead of water-based membranes that can work directly (or after simple on-board reforming) with methanol, ethanol, DME, natural gas and a variety of liquid or not fuels. This provides a tremendous advantage to everyone involved from the automobile manufacturer, to the car owner, the public policy maker, and all of those who are looking for a solution to environmental pollution and global warming now, rather than in fifty years. In China and some Western Europe countries there is already mass production of electric cars and buses with methanol range extenders. The vehicle works as follows: It still has a lithium-ion battery (approximately half the size as before) but it is also equipped with a methanol tank and a ht-pem fuel cell range extender. The range extender allows the continuous recharging of the battery, thus allowing the vehicle to double its range, refill in three minutes rather than in hours. Other benefits include lower cost vs diesel, zero harmful emissions, and operation at low temperatures (even below -20oC).

Adding up all of the above Advent’s product name would have to be:

Membrane Electrode Assemblies for high-temperature fuel cells used as range-extenders for electric vehicles with on-board methanol reforming.

As of today, the name is Li.F.E.TM technology, driving the future of electrification with Liquid Fuel Electrochemical Engines.

We welcome all our customers or partners using Li.F.E.TM technology to adopt the term, in a joint effort to communicate the future of electrification.

About the Authors

This article has been prepared by the marketing department and the executive team of Advent Technologies (https://www.advent-energy.com).

About Advent Technologies

ADVENT develops materials and components for transportation, energy, defense, and sensor applications. Advent materials enable electrochemical cells to work with multiple fuels (nat. gas, methanol, DME), rather than high-purity hydrogen and provide significant advantages for electrification and GHG reduction worldwide. A commercial truck with Advent materials refills in minutes, needs half the Li-ion battery infrastructure, has longer range and lower cost. Benefits in range, refill, cost, and clean operation apply to the APU and Portable Power (drones, defense, security) markets.

The Company was founded by world-renowned scientists with many years of industry experience. It is headquartered in Cambridge, MA with production and R&D facilities in Europe. Advent has a wide and international portfolio of patents and proven experience in scaling manufacturing.

Advent has developed, tested, patented and released to multiple customers superior materials (membranes, electrodes, catalysts) that are the heart of the next generation of electrochemical cells. Unlike the competition, Advent’s MEAs run at high temperature. This allows electrochemical cells to work with liquid fuels (methanol), biogas, aviation fuel, natural gas, not only hydrogen. Contaminants such as carbon monoxide (CO), which at a few parts per million (ppm) will kill conventional systems, can be as high as several percent (%) delivered to an Advent membrane. Because of these differences systems built with Advent inside have greater flexibility of end-user applications, simpler design, and lower cost of manufacturing.

Further Information: Chris Kaskavelis, Chief Marketing Officer, [email protected],

or [email protected]